Solutions to the Existing Limitations of the AR15/M16 Platform

The AR15/M16 platform is one of the most iconic and prolific platforms to ever be invented for civilian, military, and police use around the world. While it is a very popular design, and extremely modular, most iterations retain certain prominent limitations. Namely,

The AR15 gas impingement system results in excessive fouling in the bolt area as well as significant gas blowback in the shooter’s face, causing potential reliability issues due to the fouling.

The AR15 design incorporates a rear-mounted recoil spring as well as a buffer tube limiting the full retraction of the stock.

The rear placement of the charging handle in the AR15 requires the shooter to lift or otherwise move their head when charging the gun.

Any short stroke piston-driven AR15 will suffer from carrier tilt. Carrier tilt occurs when the piston strikes the bolt carrier off-center, causing it to tilt or otherwise move off-axis. Carrier tilt can lead to increased wear, resulting in a loss of accuracy or premature failing of the parts. We have eliminated this problem by (a) providing dual carrier paths for both the piston and the bolt carrier group, and (b) attaching the piston in a rigid fashion to the rear of the bolt carrier group, which pushes the carrier back in a uniform fashion and restricts any off-axis movement.

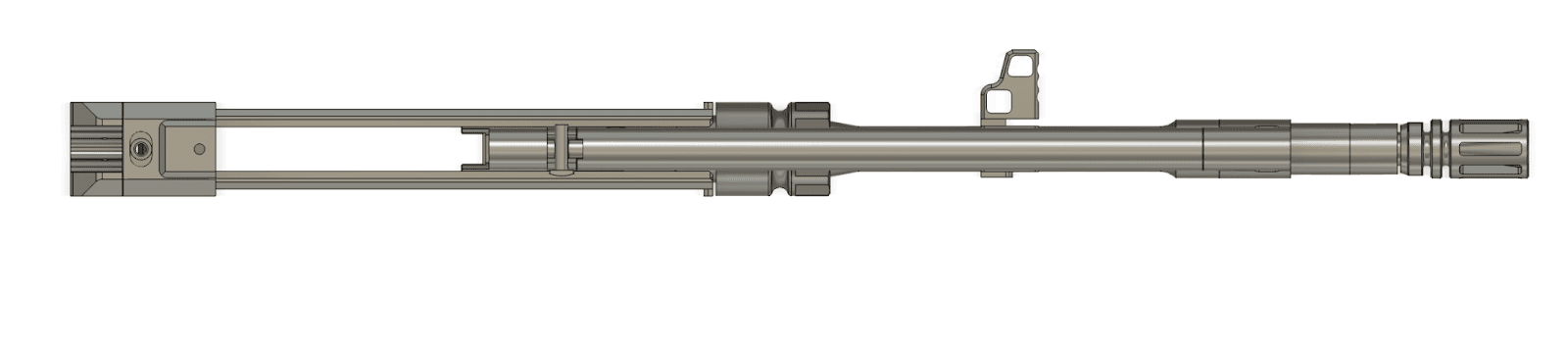

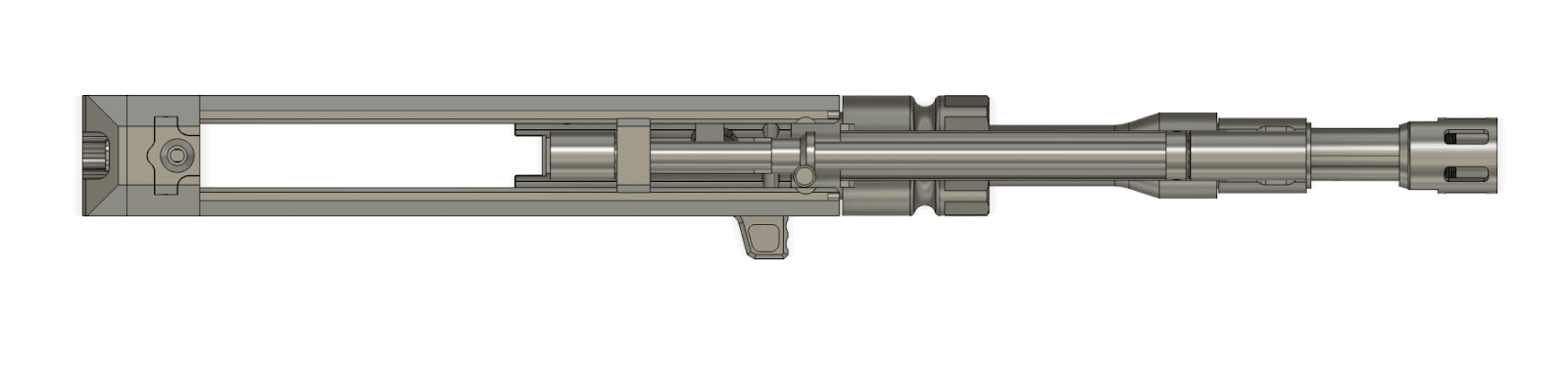

New Operating System & Interchangeable Barrels

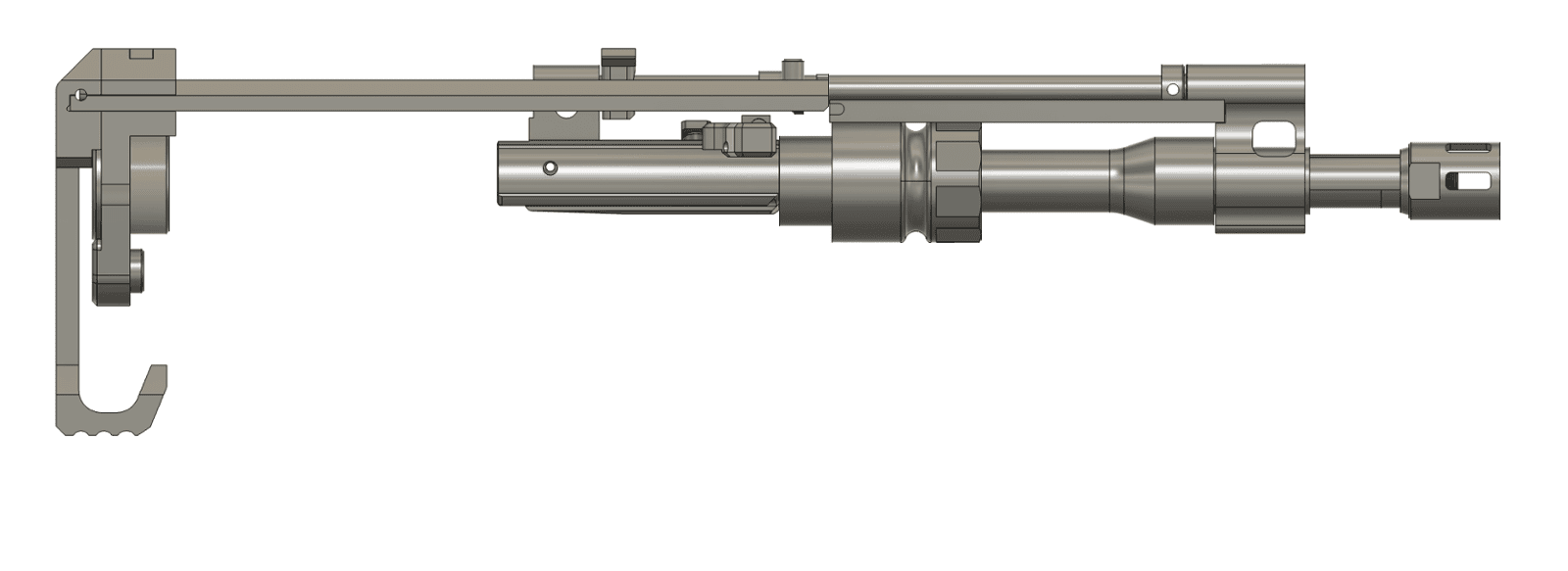

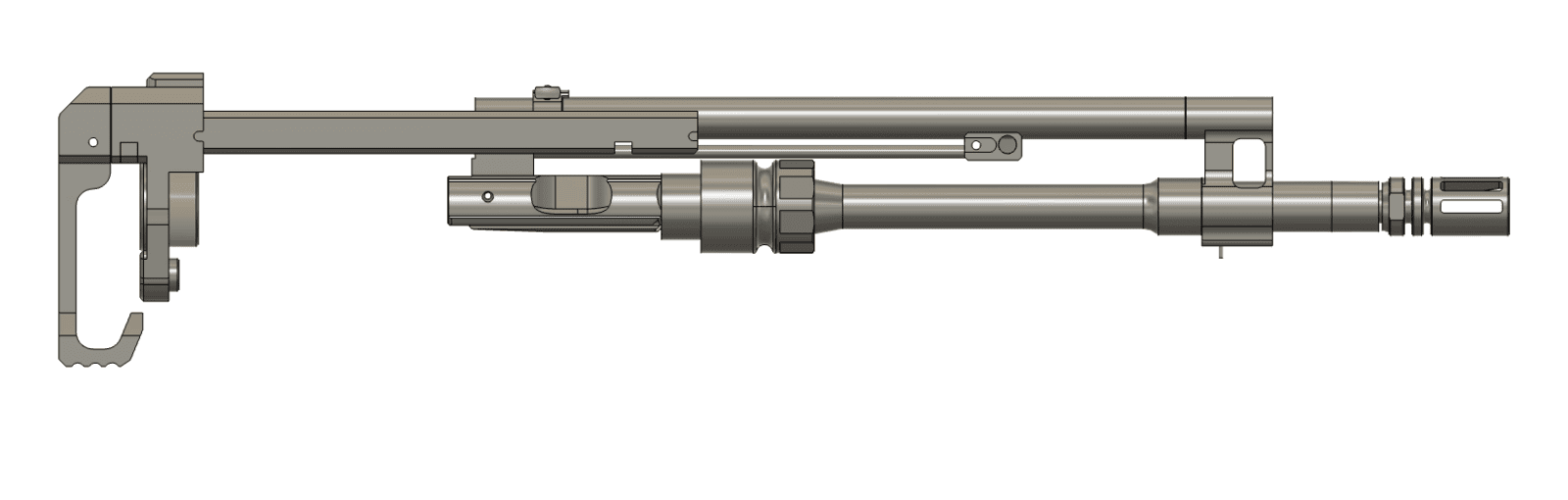

The 1.36 and Mongoose operating systems use the much more reliable long stroke AK47-style piston system instead of gas impingement.

In this iteration, it is provided in a modular piston rod fashion. The modular piston rod facilitates the easy interchangeability of different barrel lengths requiring the swapping out of a minimum amount of parts.

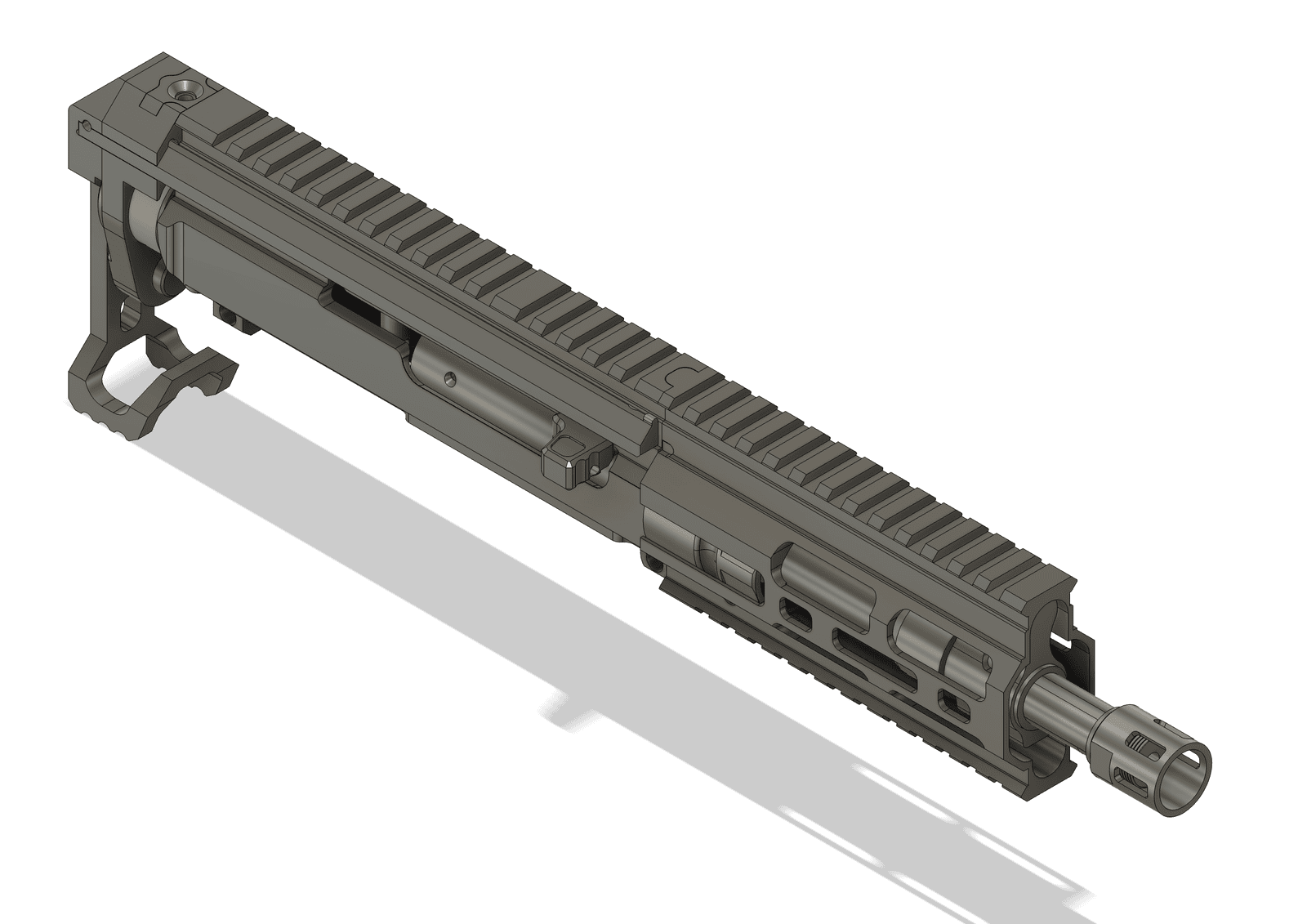

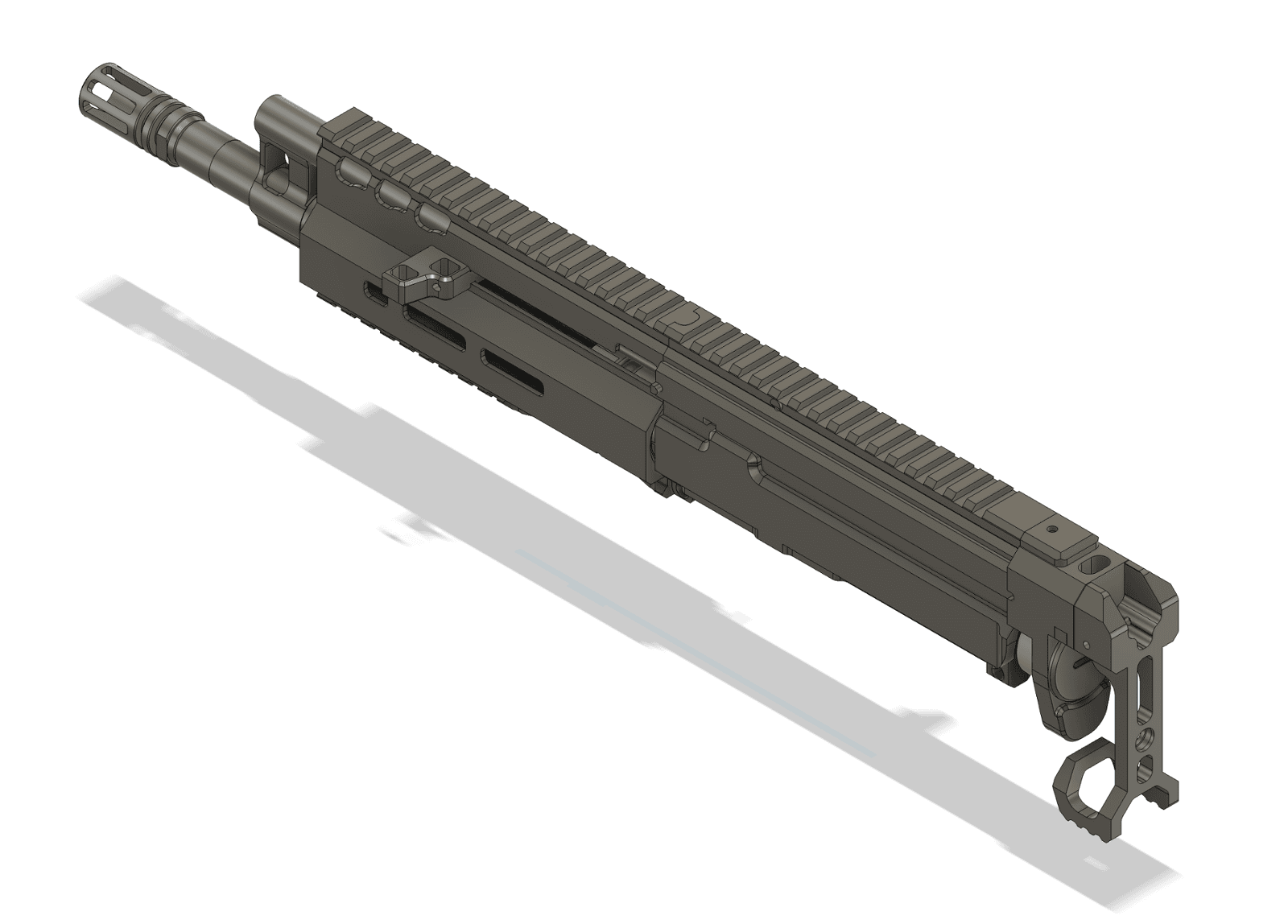

Thinness & Effective Space Utilization

In both Upper Receiver Kits, the design of the bolt carrier is specifically configured to permit the lateral placement of the rails of the retractable stock or brace in such a way as to require a minimal overall width. Even the design of the upper receiver incorporates channels to facilitate the free travel of the rails within its width.

The Mongoose chassis width is only 1.54” from outside rail to rail.

The 1.36 is even thinner. Named after its minimal width, it is only 1.36" rail to rail.

Elimination of Carrier Tilt

Charging Handle Details: Mongoose Non-Reciprocating & 1.36 Reciprocating

The Mongoose incorporates a non-reciprocating charging handle placed in such a fashion as to not require the shooter to disrupt their sight picture during charging of the gun.

The 1.36 incorporates a reciprocating charging handle to achieve the same result (the shooter need not disrupt their sight picture during charging of the gun due to the placement of the charging handle).

1.36 Chassis Width Reduction

The reason the 1.36 does not incorporate a non-reciprocating charging handle is to allow a reduction in the overall height of the upper receiver.

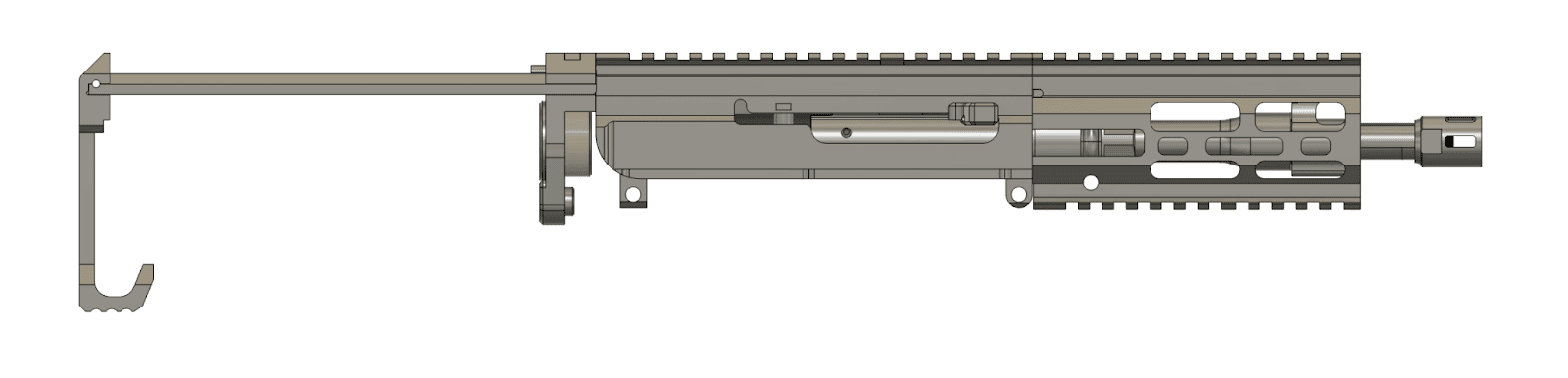

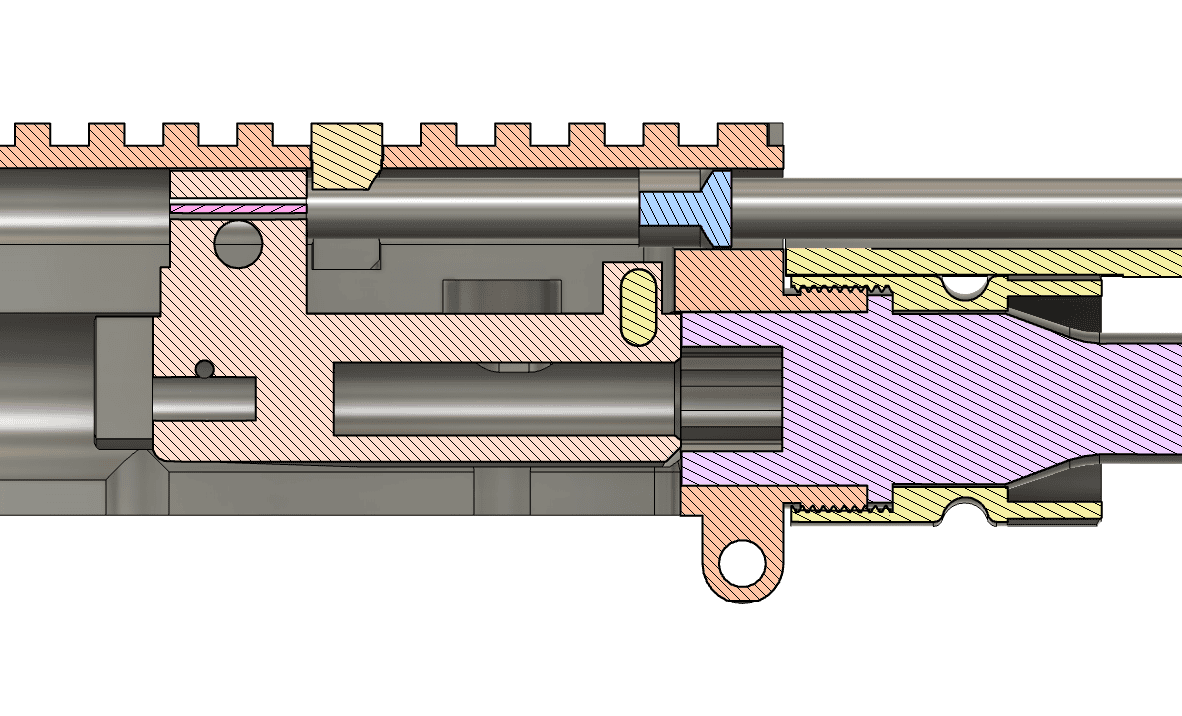

Multiple other changes have been incorporated to reduce the overall chassis width and the length of the upper receiver. Changes incorporated include:

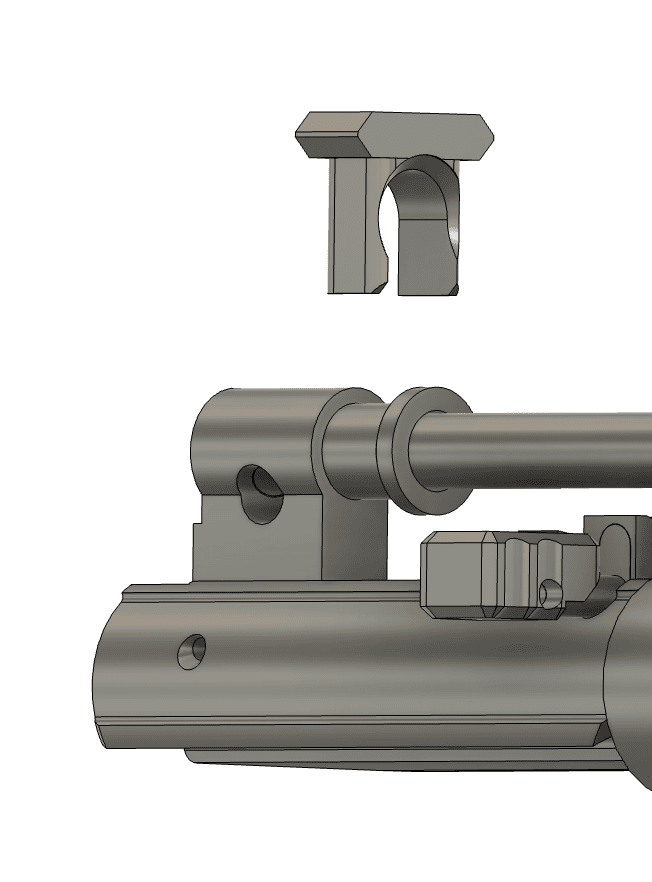

Switching from a spring-detent loaded takedown pin to a removable locking clip

2. Several width and height decreasing solutions, such as making the front rail the same width as the barrel nut, allowing exposure of the barrel nut. Designing the top interior circular portion of the front rail to have the same diameter as would be provided by a gas tube to provide a guiding channel for the gas piston and to act as a top section of the gas tube. Designing the bottom piston guide to have the same diameter of a gas tube and thus to act as a lower guide for the gas piston and thus act as the lower section of the gas tube. This proprietary part is held in place by a shelf in the gas block in front and in the rear by slots in the front rail. The combination of the interior top portion of the front rail and the bottom proprietary part act as the top and bottom of the gas tube, which would otherwise be needed, requiring an increase in overall height of the receiver.

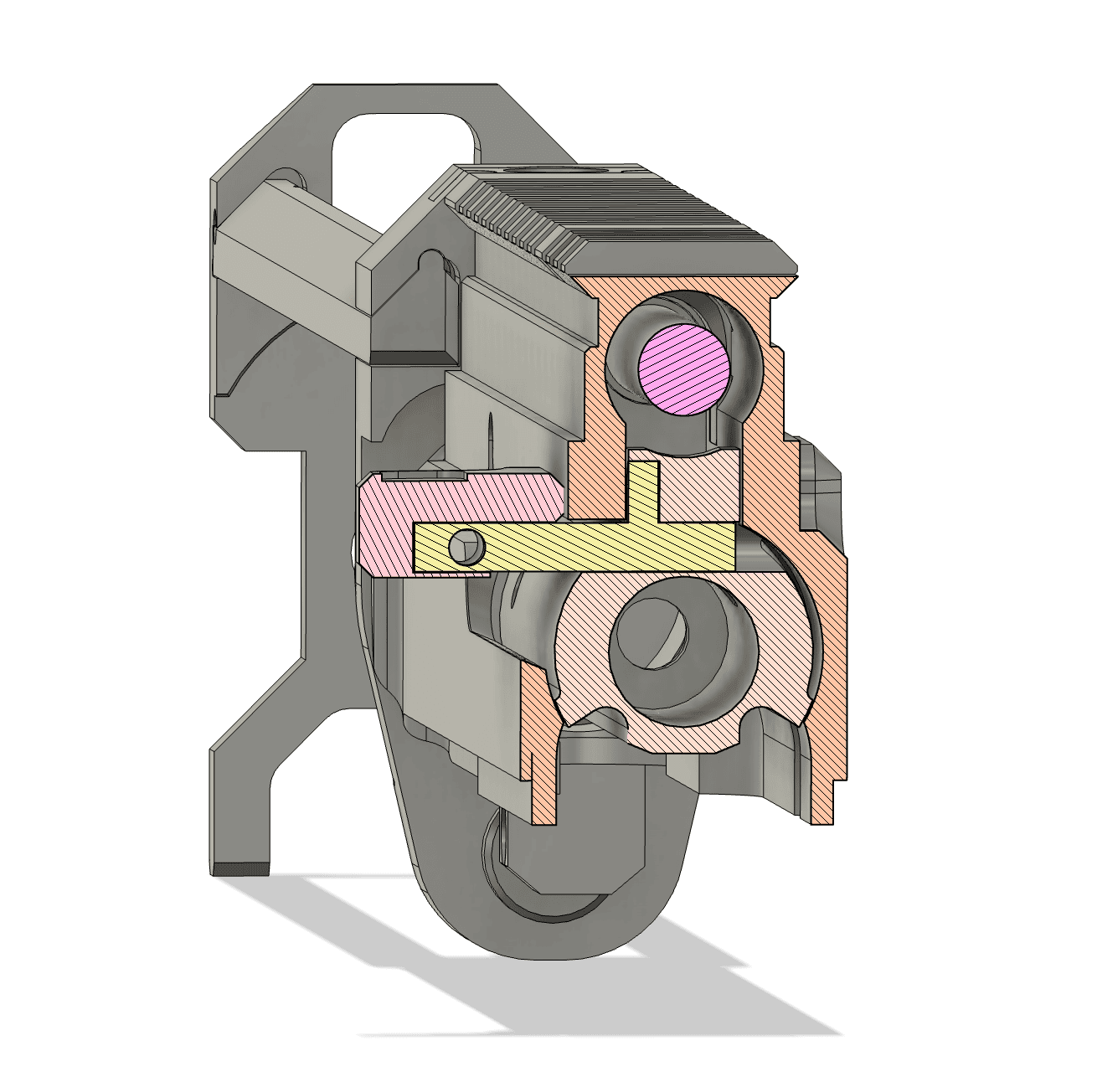

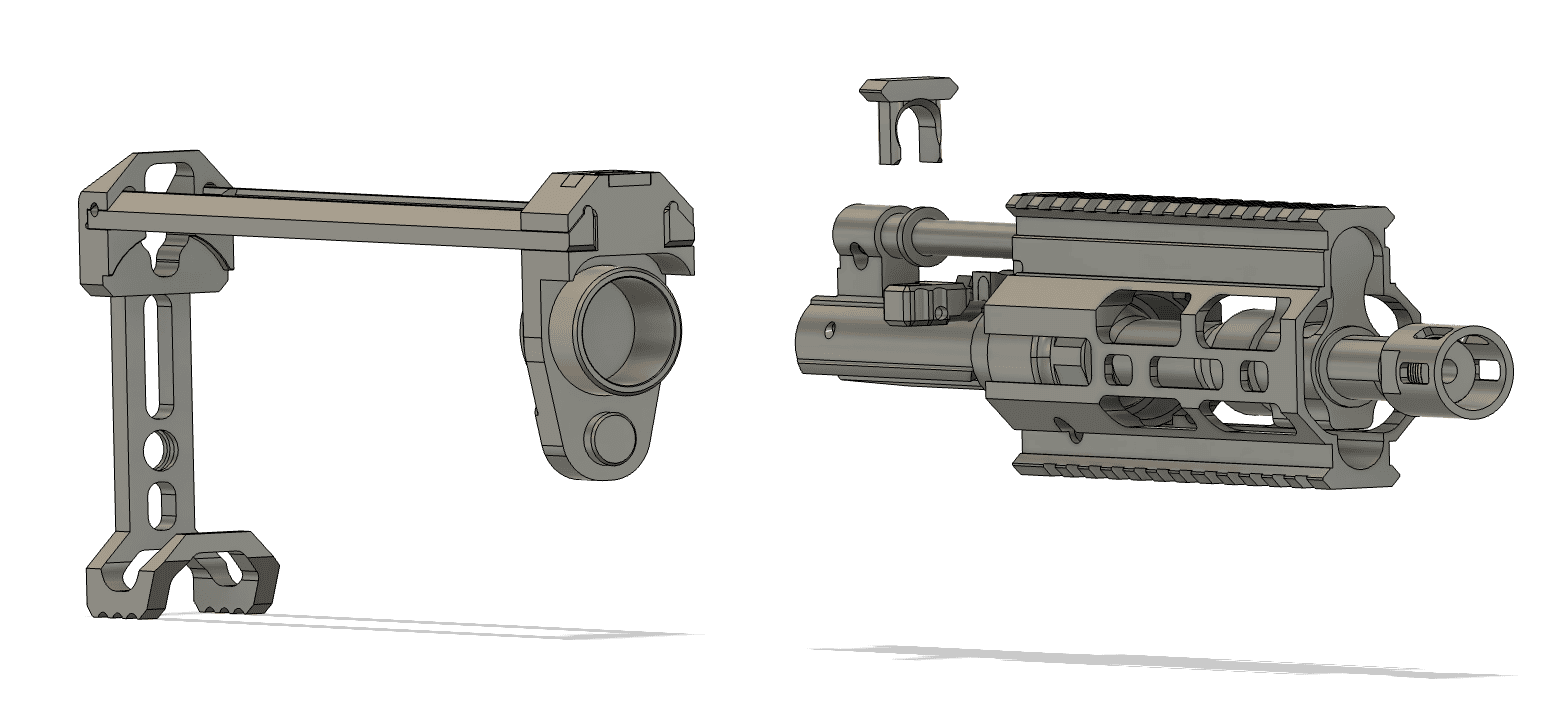

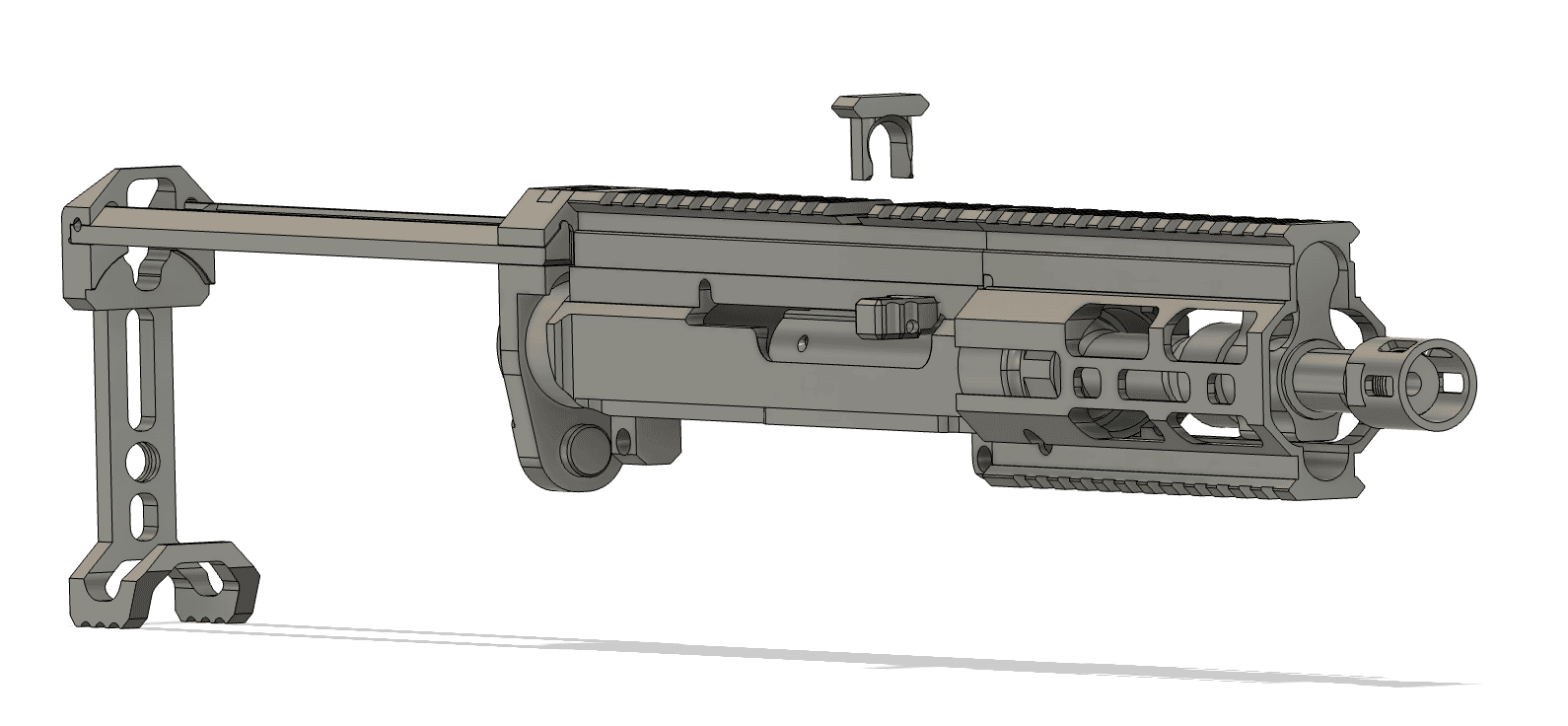

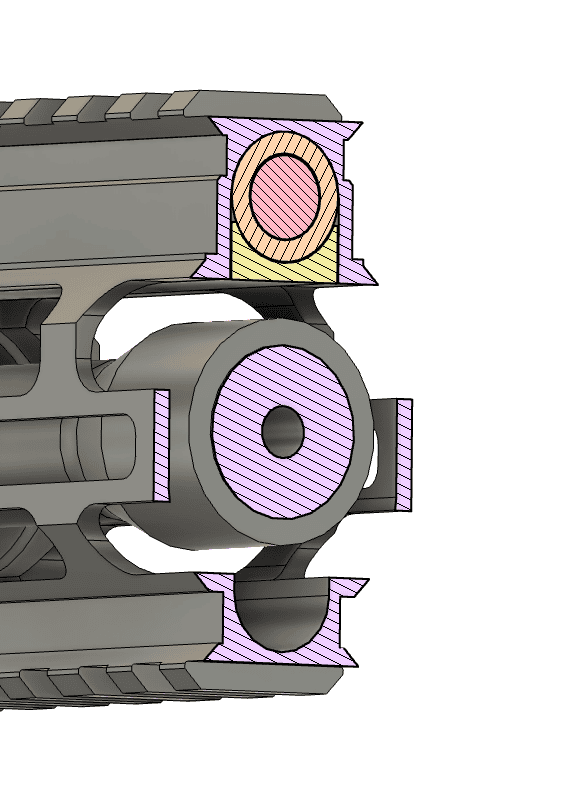

Cross Section View of the Operating System showing the incorporation of the Brace Rails, the Locking Clip Mechanism, and Charging Handle.

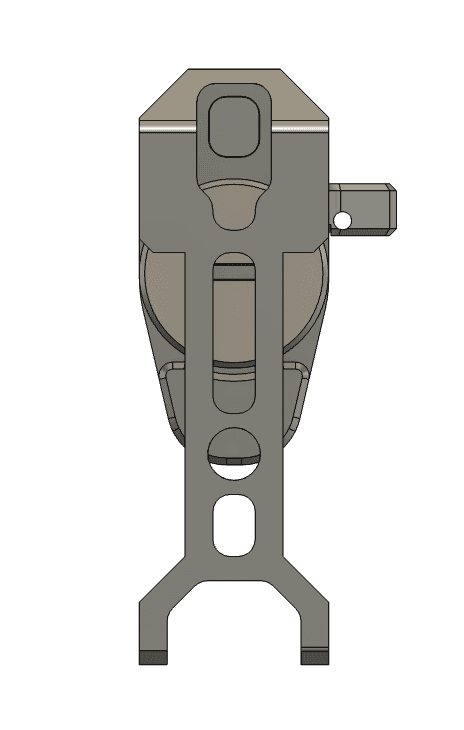

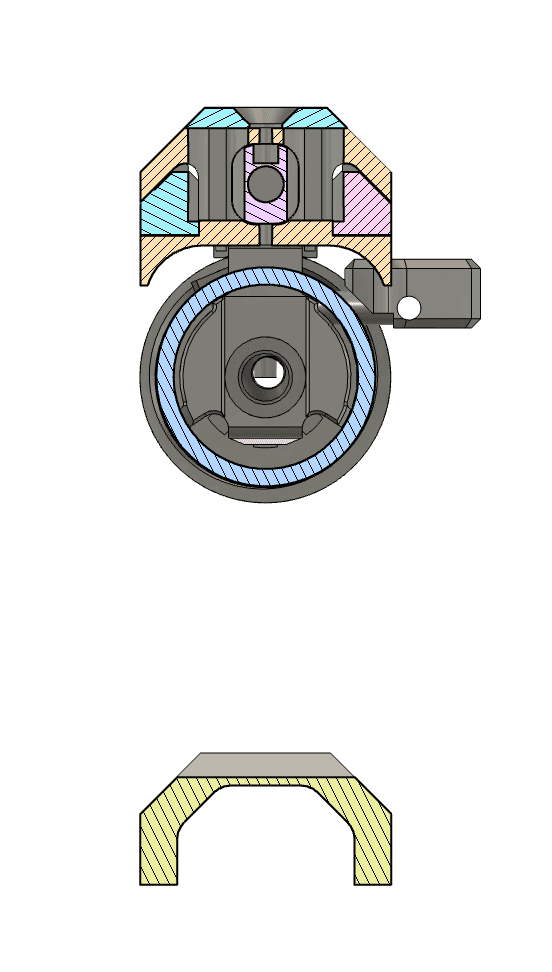

3. The redesign of the brace rails and incorporation of a pin detent brace rail locking mechanism that is almost ¾” shorter than that used by the button and slot mechanism in the Mongoose. The button of the Pin Detent Rail Locking Mechanism is incorporated entirely within the depth of the ISO BRACE.

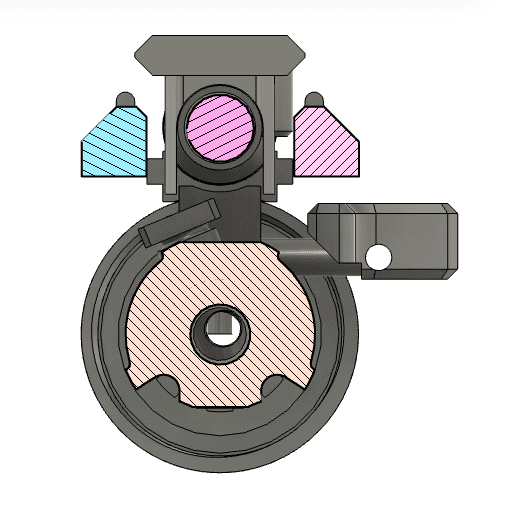

Cross Section View showing the rolling pin brace locking mechanism, the incorporated side rails, integrated bracket, and Charging Handle